Center For Crops Utilization Research Adds Value Through Innovation

Enter the Lauridsen Group’s research laboratory in Ankeny, Iowa, and you’ll find researchers developing new ways to make the raw ingredients of Iowa agriculture into ingredients for food and health products.

Space for benchtop and pilot plant research is essential for a food and health ingredient company like theirs. Before this laboratory was constructed in 2012, one place the group’s researchers conducted pilot plant experiments was at Iowa State.

The Center for Crops Utilization Research (CCUR) industry incubator in the food sciences building provided space and technology for benchtop and pilot plant research to Proliant. The company has been part of the Lauridsen Group, Inc. (LGI) holding group since the mid-1990s.

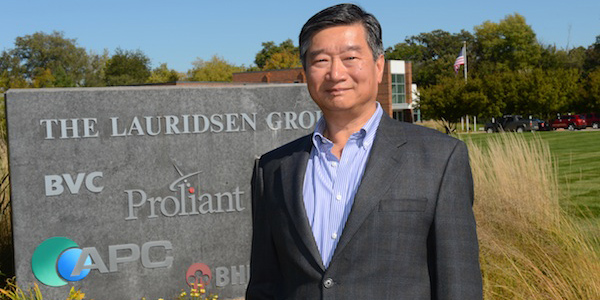

“We used the incubator because it helped us in the beginning when we were small,” says Chia-Wei Chang (MS ’81 meat science), the executive vice president of LGI, formerly the president and CEO of Proliant Meat Ingredients. “The CCUR industry incubator is important to small Iowa companies.”

The process Proliant researchers developed at CCUR involved recovering Bovine Serum Albumin, a protein from bovine blood in purified form so it could become a specialized material used in diagnostic, life science research, biopharmaceutical and veterinary vaccine industries. This process was perfected at CCUR, and Proliant built a plant in Boone, Iowa, to commercialize their production of the material.

Proliant now employs 40 people at the plant in Boone, and the company plans to build an identical plant in New Zealand. Proliant and LGI have grown exponentially since their CCUR days. The global reach of LGI now includes 49 plants and facilities in the United States, Europe, Asia and Latin America. When Proliant first started working with CCUR, the company owned two plants.

Lawrence Johnson, director of CCUR, says it is rewarding to watch small businesses develop new processes and products, commercialize and grow as companies.

“I don’t like just developing technology and putting it on the shelf,” Johnson says. “I like to see new products come out and go down a processing line.”

Johnson says what LGI does—create ingredients, as opposed to complete products—is something Iowa entrepreneurs have a unique opportunity to do.

The proximity of raw agricultural materials gives Iowans in the food industry opportunities to break apart those raw materials when they are fresh.

Chang agrees being in an agricultural state is good for his business.

“Fresh raw materials always equal higher quality products,” Chang says.

If fresh materials are a great starting point for an agriculture-based company, adding value to those materials by innovation is what grows a company.

“The reason companies can continue to grow is that they can add value to a product,” Chang says. “That’s why this new lab is important to our future growth.”

Proliant hires talented Iowa State alumni frequently to discover new ways to add value to their products.

Chang says companies like LGI need people with many different kinds of skills.

He says it’s important to know that scientists are not necessarily limited to working in a lab. His scientific background helped him sell Proliant’s products, but he has learned business skills along the way.

“What is most important is the learning mind,” Chang says.